Grill Light

The final version of the grill light is in production! It's mounted behind glass, inside the hopper. A magnet (specified and designed by me) triggers a Hall-effect sensor on the PCB, switching the light on/off.

01

Overall Rendering

The grill light illuminates the cooking surface, making cooking at night a much easier task. The plastic housing sits behind masked and branded glass.

02

Original Design (V1)

This design was one of my earliest projects and thus had quite a bit of room for improvement! The part count was high, and the assembly time was high/risky as a result. Part count: 9+fasteners

.jpg)

Replaced with V2 Assembly below on this page

SPI-A1 polished PC for maximum reflection

Upper housing seen in assembly photo

Replaced with V2 Assembly below on this page

03

Assembly View (V2)

This streamlined design reduced cost, complexity, and assembly time. It represents a "win" for everyone--customers, engineers, and manufacturers. Part count: 4+fasteners

04

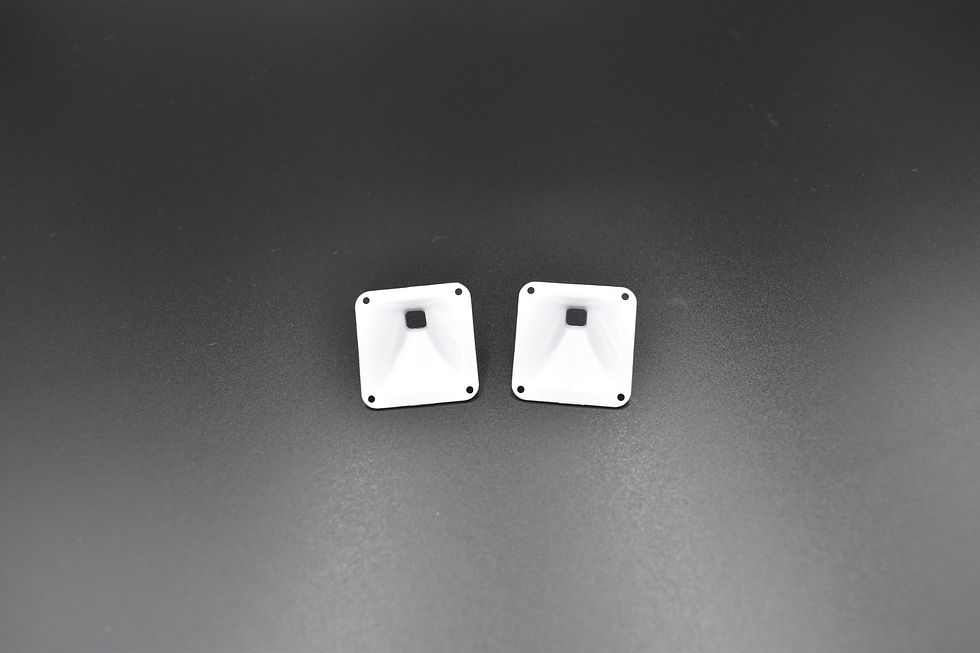

Plastic Housing (Front)

This is both the housing and the reflector for the grill light. It sat close to the glass but with a small air gap to prevent overheating. It also holds the PCB with the Hall-effect sensor.

_JPG.jpg)

05

Plastic Housing (Rear)

This plastic part attached to the front housing and also mounted the light to the inside of the hopper. It has several cutouts for the harnesses/connectors as well as to allow airflow. This area of the grill gets very hot, so I did not want stagnant air to be trapped.

06

Magnet Testing

I worked with the firmware engineer (seated at the computer) to test a variety of magnet strengths. The goal was to determine the minimum mT reading needed to trigger the Hall-effect sensor. The firmware engineer is taking mT readings of the magnet every 0.5 seconds. The Samarium Cobalt magnet prices increased exponentially with thickness, so it was imperative for this to be a data-driven decision.