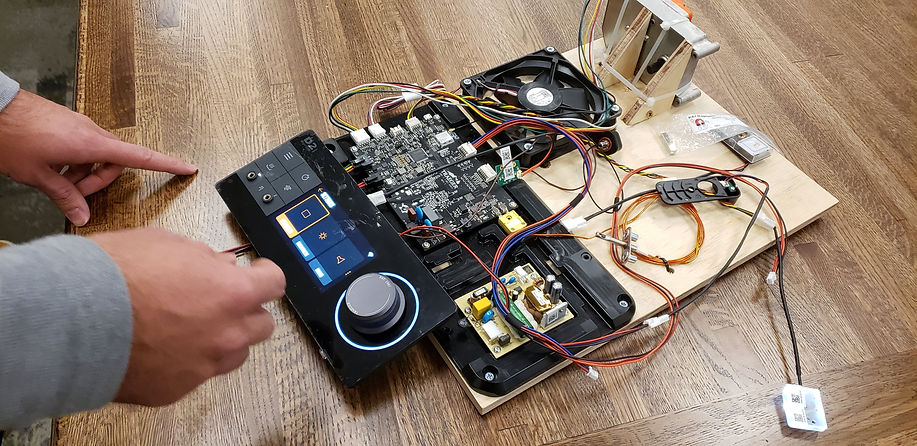

Smart Combustion Assembly

This assembly consists of 2 large injection-molded plastic pieces and 2 boards, the motherboard and the power supply. The PCBs are mounted to the rear housing, and the rear housing is mounted to a wall inside the hopper. The front cover is then attached to protect the user from electrical shock. Check out some of the testing done on this assembly, as it represents the "brains" of the grill.

_JPG.jpg)

01

Front Cover

This was the first plastic piece I can remember completing, and there were quite a few lessons learned along the way. The Smart Combustion logo is made via emboss as well as a different texture.

02

Rear Cover

This part was one of the most challenging parts to model as a newer engineer. The unique geometry primarily serves as cable routing, as 10-12 different harnesses came together in this assembly.

_JPG.jpg)

_JPG.jpg)

03

Rear Cover (Back View)

The Rear Cover had many openings on the back at the request of the factory to allow for easier quality testing. The factory operator could access the ports directly via these openings and ensure all electrical connections worked.