Miscellaneous

Here is a collection of random tasks/activities I completed while at Traeger, but many of them applied to multiple projects or were general skills learned.

.jpg)

01

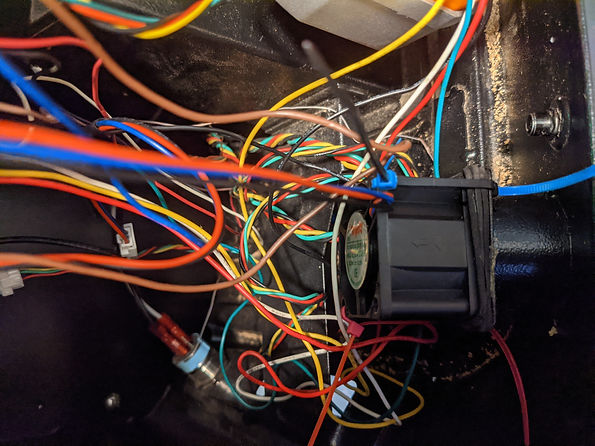

System Integration Testing

Three different projects of mine are visible in this photo! While this was primarily a task for the firmware engineers, I would occasionally support in case of a mechanical issue. You can see the Controller, Smart Combustion Assembly, and parts of the Grill Light in the photo.

02

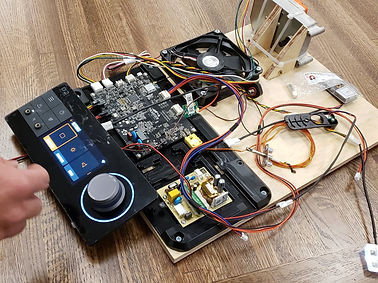

High-Pressure Fixture

I utilized our hydraulic bottle jack press to mock up a high-pressure fixture (found in our factories) as a quick way to prototype such applications. One common use was to apply the glass/adhesive to the plastic faceplate of the Controller I designed, as the factory used up to 100 psi.

03

Thermocouple Data Logging

As grills are very thermally-sensitive systems, we used thermocouples to track temperatures of various areas. For example, electronics could never surpass 185F. We also used thermocouples to track temperatures of the grill grates themselves, ensuring the PID system was tuned correctly. Thermocouple testing was crucial in development of the Grill Light, as it got very hot being next to the glass and barrel of the grill.

04

Selecting Limit Samples

For many parts I designed, particularly those with anodizing, paint, etc, I had to select a range of "limit samples" since no 2 manufacturing "batches" will be exactly the same. As you can see, this sample set of knobs for the Controller ranges in both color and luster. I selected 9 to be acceptable, and I sent them to the factory to use as a go/no-go test.

05

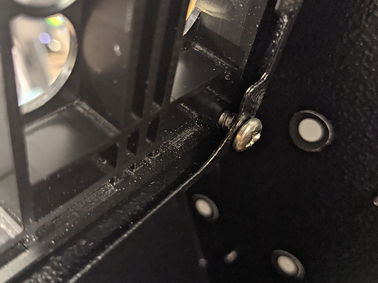

3D Scans

For select parts that proved challenging in manufacturing, we ordered 3D scans to more easily identify the problem areas and report back to manufacturers. This was particularly helpful in the Hopper Wrap. The white dots help locate the laser during the scan process.

06

Anticipating Manufacturing Defects

As discussed with the Hopper Wrap, sometimes complex parts did not come off the tool as designed. In order to anticipate the ramifications, I would try to come up with a list of as many defects as possible and then prototype them (usually an SLA print), and then test with any mating parts. This photo here represents Controller pockets on the Hopper Wrap that are too shallow, too deep, nonplanar flanges, etc. I mounted a Controller and ran water ingress tests to see what would happen.

07

Water Ingress Testing

As an outdoor product, every single part of the grill needed to pass water ingress testing. The grills were IPX3 rated, so a fixture was used to direct 15 psi water at a 60° angle. The test would typically run for an hour. White paper was placed inside the component being tested, and the paper would turn pink upon contact with water.