Product Development Work

Here is a selection of grill components I've designed & owned all the way through manufacturing/product release. There are more, but I must respect Traeger IP and only showcase work in released products.

I am working on getting my designs from Dyno Nobel...

_JPG.jpg)

01

This controller is my proudest achievement thus far! I was the lead ME on it and worked through numerous difficult, complex manufacturing challenges. A cap-touch glass screen and a 16-LED continuous light ring added to the sophistication of the design. Part count: 11+fasteners

02

The grill light went through 2 iterations to dramatically reduce part count and simplify manufacturing. The light illuminates the cooking surface thanks to a Hall-effect sensor and a Samarium cobalt magnet. This design has greater water ingress protection as well, sitting behind glass rather than outside of the grill. Part count: 4+fasteners

03

I contributed to the design of the hopper wrap, particularly around the controller mount area. This deep-drawn part was the culmination of numerous design challenges related to deep-draw, giving me some rather unique sheet metal experience.

04

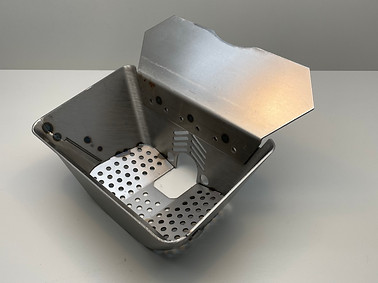

I designed the cut-and-fold firepot for the grill, which was the culmination of a 5-factor DOE using Design Expert software. The DOE helped guide feature selection such as hole size, hole pattern, and floor angle. The DOE was one of the highlights of my Traeger career.

_JPG.jpg)

05

This is an injection-molded PCBA/power supply chassis and housing for the 2022 Timberline grill. This was the largest plastic part I worked on, and there were a couple of lessons learned by failure along the way. Part count: 4+fasteners